ENGINEERED TO SERVE THE WORLD OF TOMORROW

Multi-B Sdn Bhd manufactures Translite low voltage power distribution system, designed for high rise buildings such as Condominiums, Institutions of Higher Learning, Commercial and Office Complexes, Hotels, Hospitals, Airport Terminals, Military Installations and other High Security Facilities.

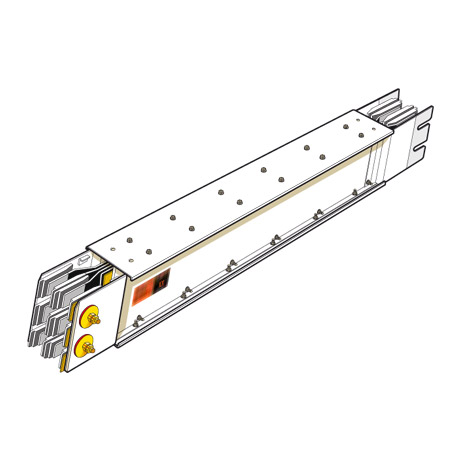

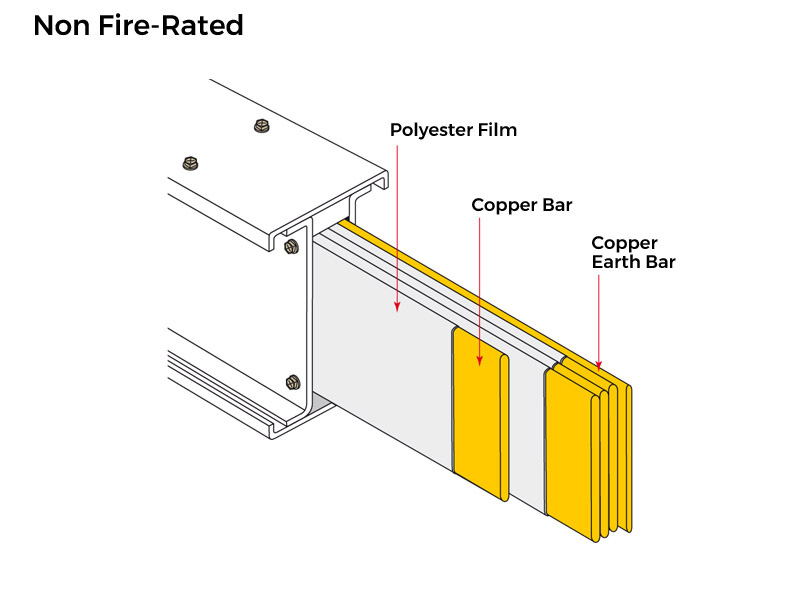

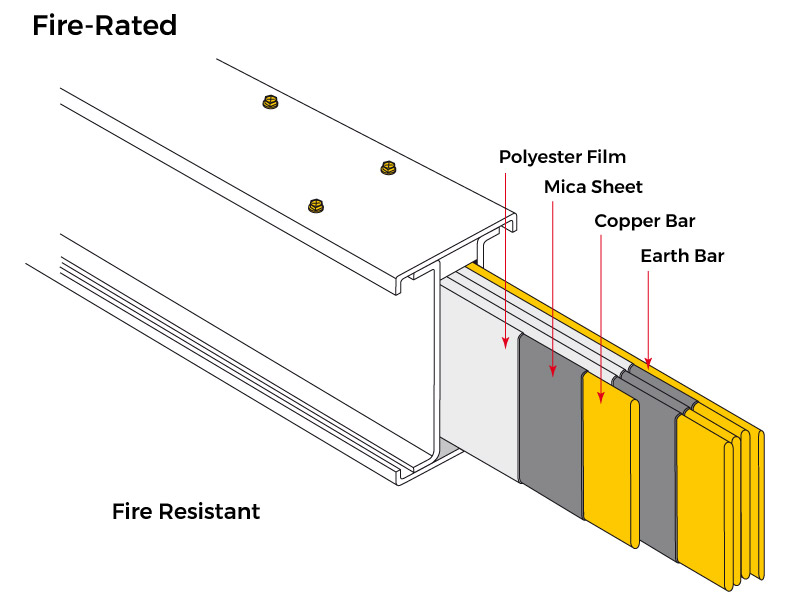

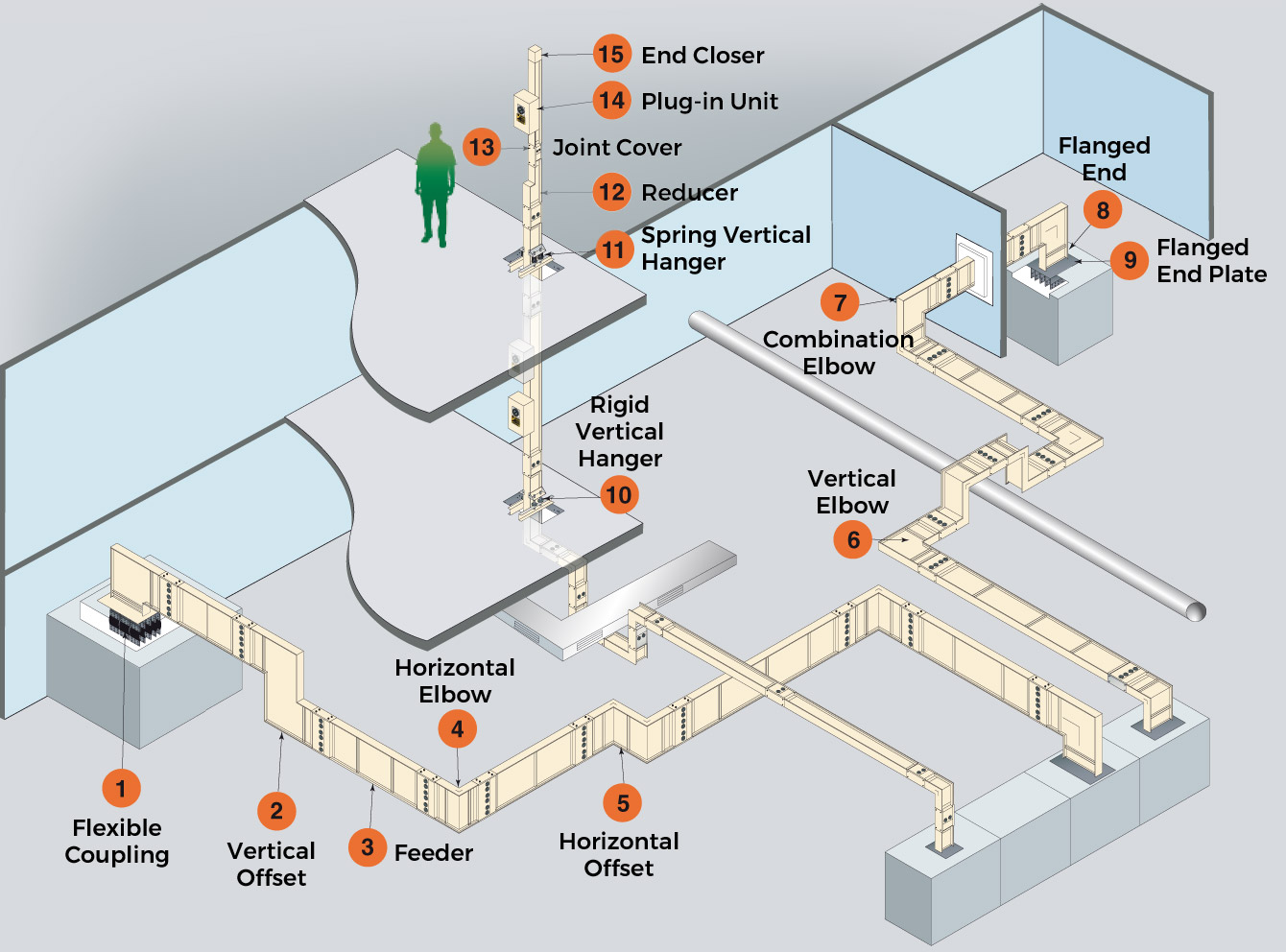

Translite MF Busduct system comprises a compatible line of feeder and plug-in busducts and accessories. Translite MF Busduct is available in standard 3-meter length with ratings of 600 Amp to 6000 Amp. It comes with aluminium, or copper conductors.

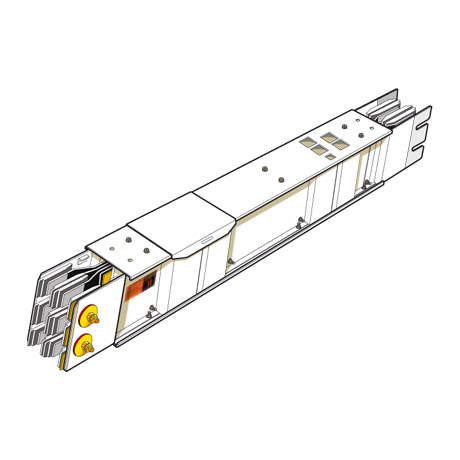

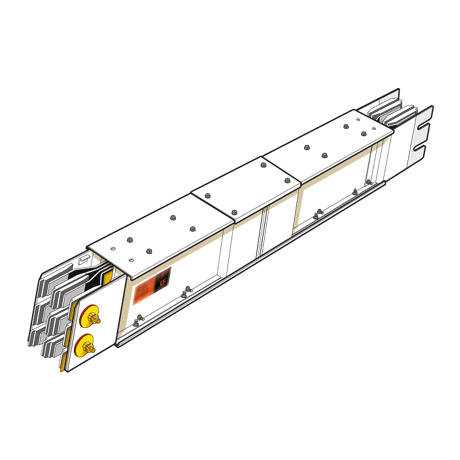

Feeder

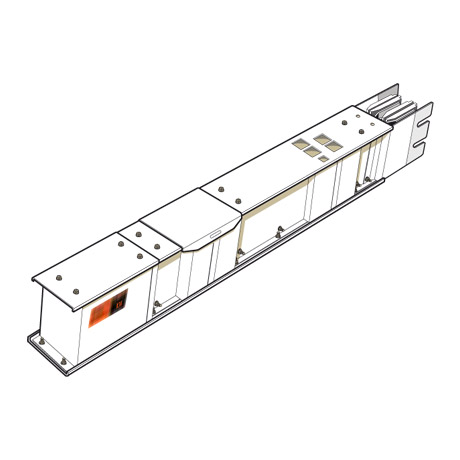

Plug-in Feeder

End Closer

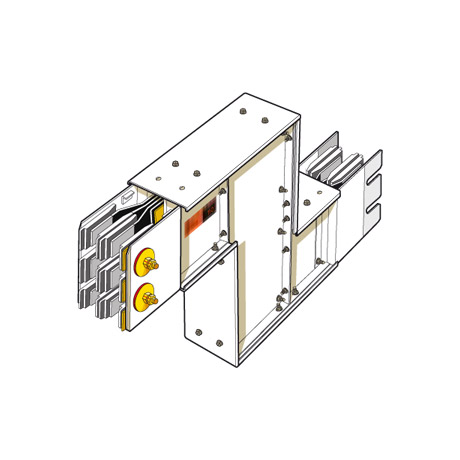

Expansion Joint

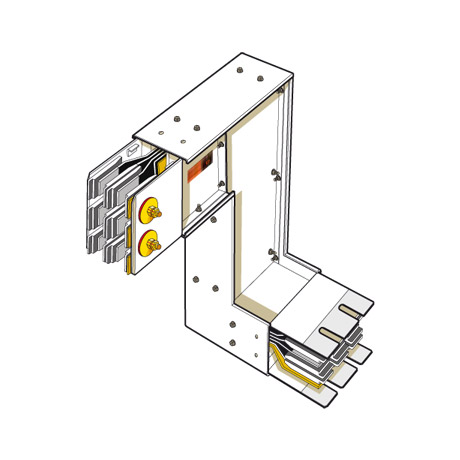

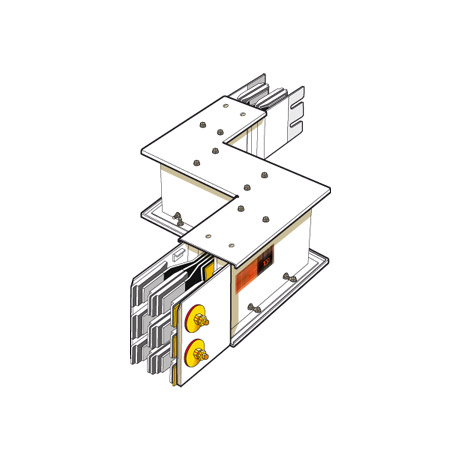

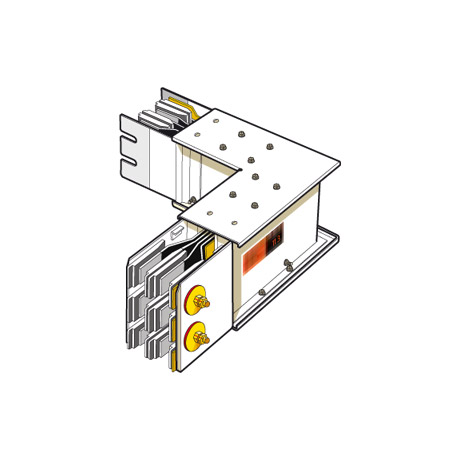

Combination Elbow

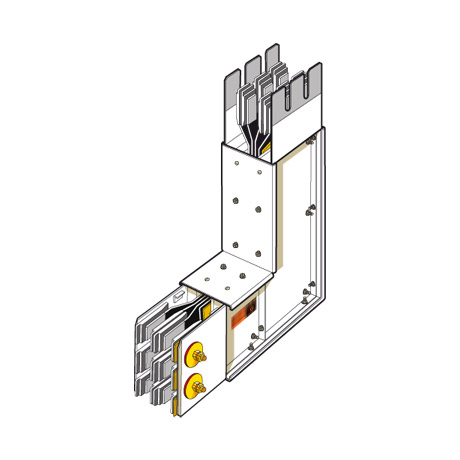

Vertical Elbow

Vertical Tee

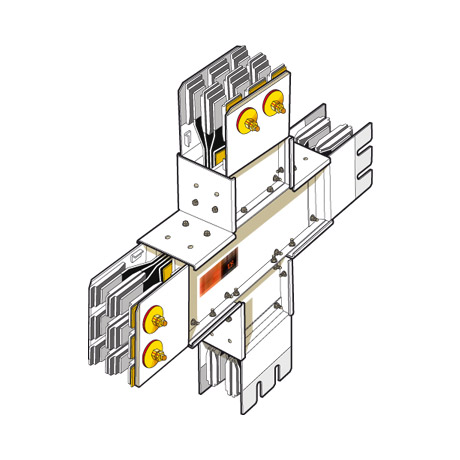

Vertical Cross

Horizontal Offset

Vertical Offset

Reducer

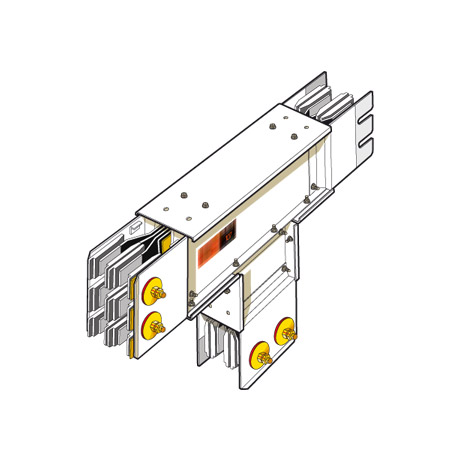

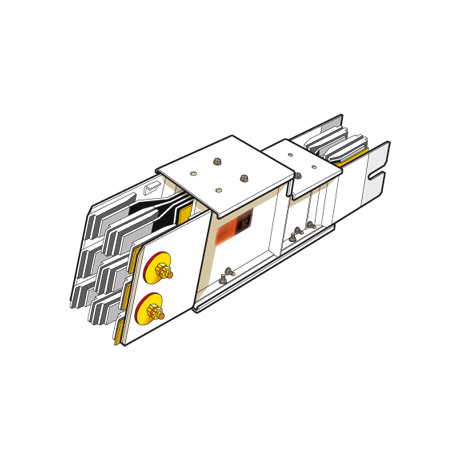

Horizontal Elbow

Flanged End

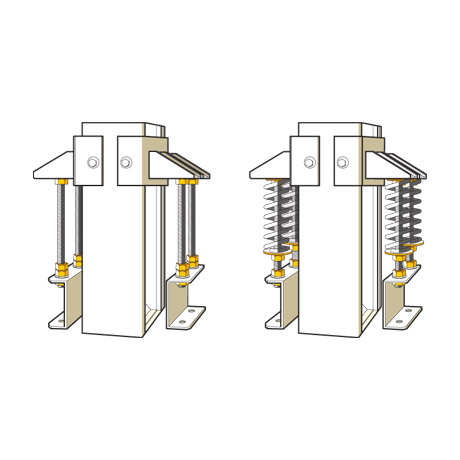

Rigid / Spring Vertical Hanger

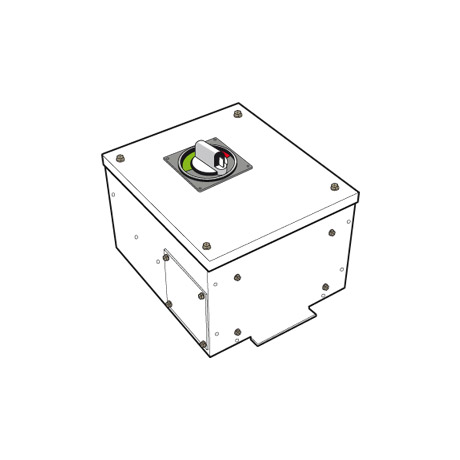

Plug In Unit

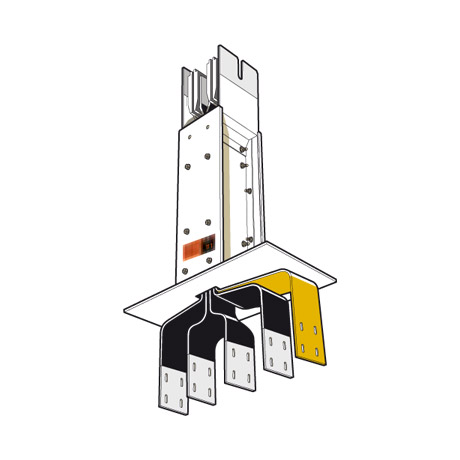

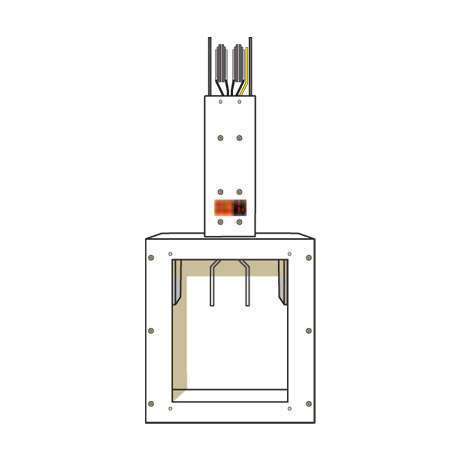

Cable Entry Box

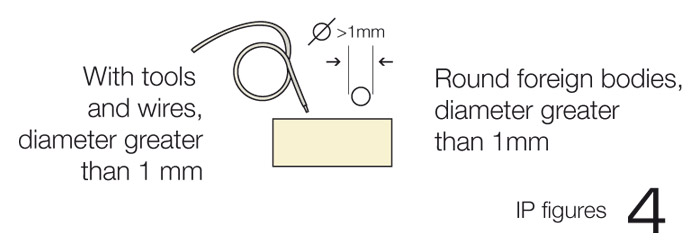

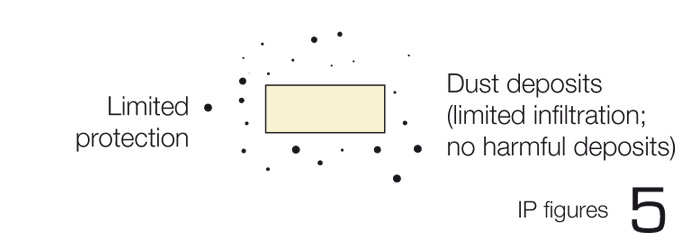

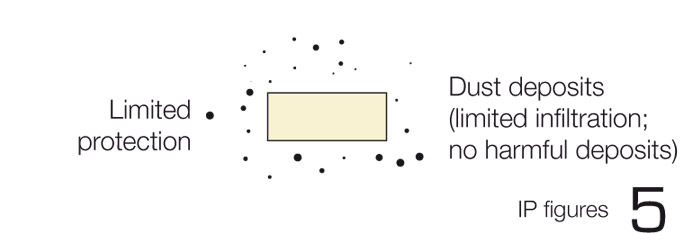

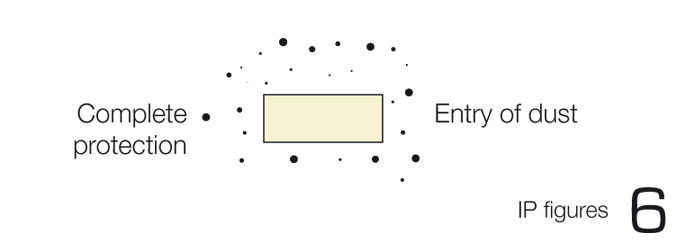

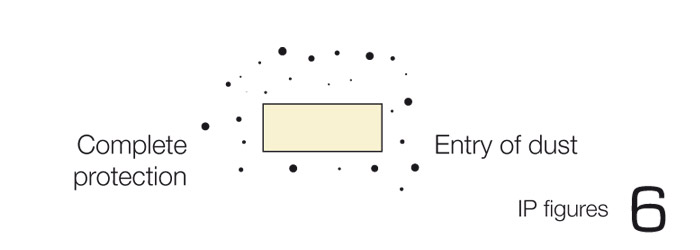

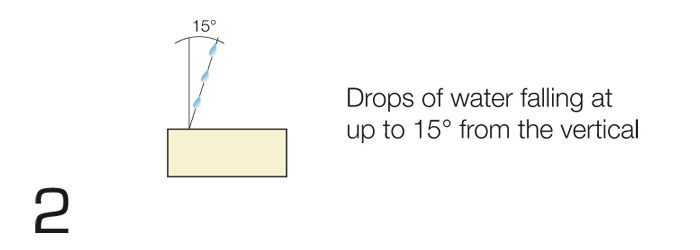

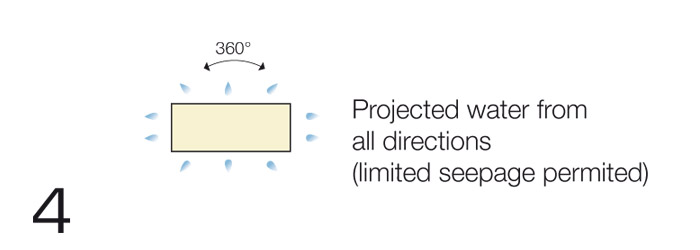

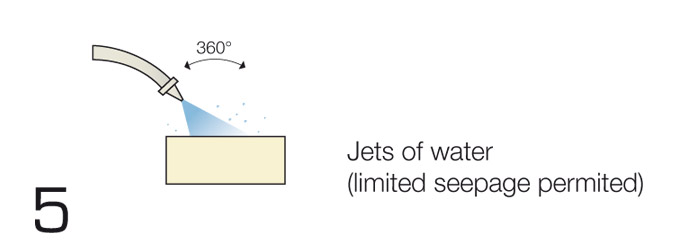

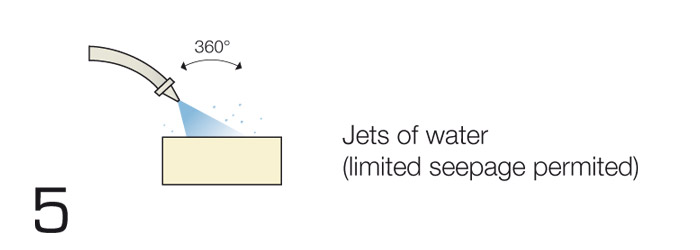

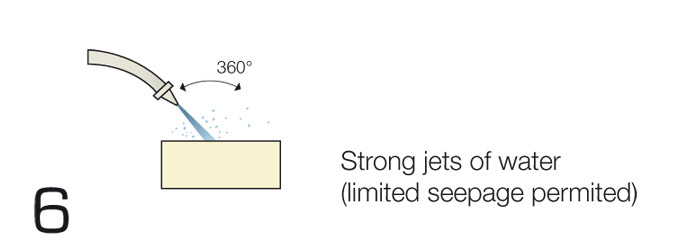

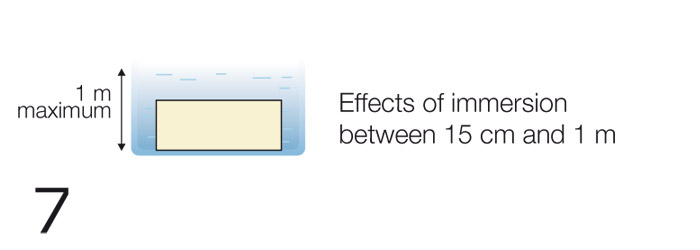

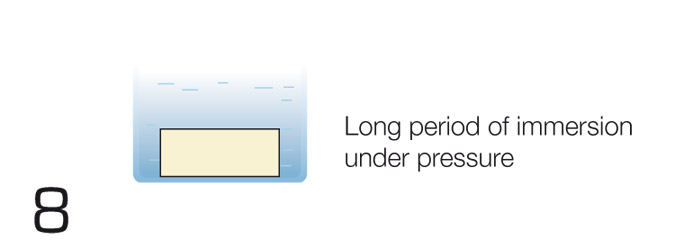

The Translite MF Busduct System is recommended for electrical power transmission and distribution in high rise buildings and complexes. It is available in different IP protections ranging from IP42 to IP68.

Before installation, the busduct route and position must be determined and ensured absence of any obstacles.

OF SOLID OBJECTS

WATER

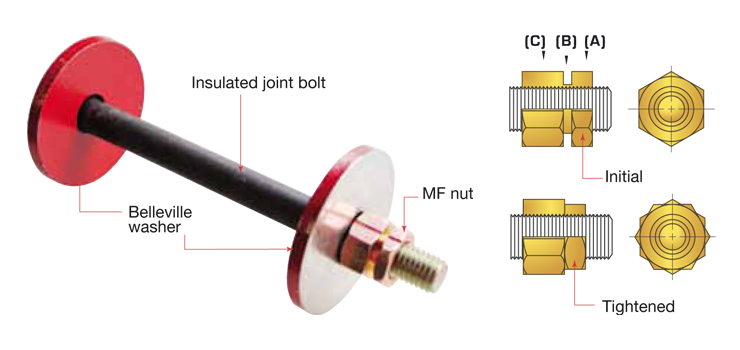

The busduct joint is the most important component of the busduct system. Therefore, it is imperative that the joints are installed and secured correctly. Improper jointing will result in power loss and equipment damage.

- Before jointing, clean the busduct conductors to ensure that they are dust-free.

- For Ampere rating of 600Amp and 800Amp, temporarily remove the joint bolt. For Ampere rating that is larger than 800Amp, it is not necessary to remove the joint bolt.

- Align the joint ends and slide them in until the duct joint touch the stopper. (see Fig.4) When re-inserting the joint bolt, make sure the belleville washers are properly installed with the convex side facing out. (see Fig.5)

Set the centre line and level together.

Fit together till the duct joiners touch the stoppers.

Tighten the “MF” nut by special ratchet wrench till the neck part of the nut is broken and locked.

Attach the joint cover with M6 bolt & nut.

Completed joint.